In today’s competitive manufacturing landscape, the art of precision engineering in manufacturing processes stands as the cornerstone of quality production and innovation. This fusion of scientific principles and meticulous craftsmanship drives industries forward, enabling the creation of components with tolerances measured in microns and surface finishes that meet the most demanding specifications. The evolution of precision engineering has transformed how we approach manufacturing, particularly in specialized applications like gasket production, where exact specifications directly impact performance and reliability.

The foundation of modern precision manufacturing

Precision engineering represents the culmination of centuries of manufacturing evolution. What began with rudimentary hand tools has progressed to computer-controlled machinery capable of achieving accuracy previously thought impossible. This progression hasn’t simply been about better tools—it reflects a fundamental shift in how we conceptualize manufacturing processes. The marriage of advanced materials science, computational modeling, and automated fabrication has elevated manufacturing from mere production to a sophisticated discipline requiring deep technical expertise.

Companies at the forefront of precision engineering invest heavily in both equipment and human capital. Engineers with specialized knowledge in materials behavior, thermal dynamics, and stress analysis collaborate with skilled technicians who understand the nuances of machine operation. This combination of theoretical knowledge and practical experience creates manufacturing environments where precision isn’t just a goal—it’s the standard operating procedure.

Advanced cutting technologies revolutionizing gasket production

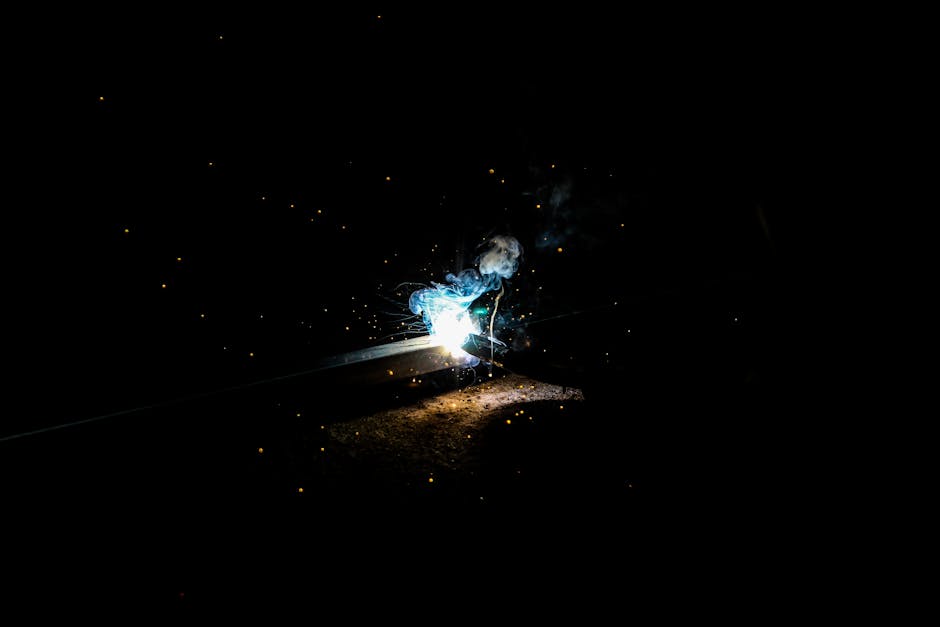

The gasket industry exemplifies how precision engineering transforms manufacturing outcomes. Modern gasket production relies on cutting-edge technologies that ensure consistent quality across thousands of units. Laser cutting gaskets represents perhaps the most significant advancement in this field, offering unprecedented precision for even the most complex geometries.

Laser cutting technology utilizes focused light beams to create clean, precise cuts through various gasket sheets without the mechanical pressure associated with traditional die cutting. This contactless approach eliminates deformation risks while achieving tolerances as tight as ±0.05mm. For industries where sealing integrity directly impacts safety and performance—such as aerospace, automotive, and chemical processing—this level of precision isn’t merely beneficial; it’s essential.

Premium manufacturers like Donit have embraced these advanced cutting technologies as central to their production processes. By integrating computerized design systems with automated cutting equipment, these industry leaders achieve remarkable consistency while maintaining the flexibility to produce custom gasket solutions for specialized applications. The art of precision engineering in manufacturing processes becomes particularly evident when examining how these companies balance standardization with customization capabilities.

Material science advancements enhancing gasket performance

Precision engineering extends beyond the cutting process to encompass material selection and development. Modern gasket sheets incorporate sophisticated composite structures designed for specific operating environments. These materials result from extensive research into how different substances perform under varying temperatures, pressures, and chemical exposures.

Engineers developing gasket materials must consider multiple performance factors simultaneously. A gasket that excels in high-temperature environments might perform poorly when exposed to certain chemicals. Similarly, a material with excellent compression resistance might lack the flexibility needed for specific applications. The challenge lies in finding the optimal balance—a task requiring both scientific knowledge and practical manufacturing expertise.

Advanced testing methodologies allow manufacturers to simulate real-world conditions before finalizing material formulations. Thermal cycling chambers, pressure testing equipment, and chemical exposure tests provide data that informs both material development and application recommendations. This science-driven approach exemplifies how the art of precision engineering in manufacturing processes combines theoretical understanding with practical application.

Quality control systems ensuring manufacturing excellence

Even with advanced materials and cutting technologies, consistent quality requires sophisticated monitoring systems. Modern precision manufacturing facilities implement multi-layered quality control processes that verify compliance with specifications at every production stage. These systems combine automated inspection technologies with human expertise to detect deviations that might compromise product performance.

For gasket manufacturers, dimensional accuracy represents just one quality parameter among many. Surface finish, material consistency, and edge quality all influence how effectively a gasket will perform in service. Leading manufacturers implement statistical process control methods that continuously monitor these parameters, allowing immediate adjustments when variations approach tolerance limits.

Optical scanning systems can now verify gasket dimensions against CAD models in seconds, identifying deviations invisible to the human eye. This technology, when integrated with production databases, creates comprehensive quality records for each manufacturing batch. Customers increasingly request this documentation as part of their own quality assurance processes, particularly in regulated industries where traceability requirements continue to expand.

The future of precision engineering in gasket manufacturing

As manufacturing technologies continue advancing, the boundaries of precision engineering expand accordingly. Emerging technologies like additive manufacturing offer new possibilities for gasket design and production, potentially enabling structures impossible to create through traditional cutting methods. These innovations don’t replace existing precision techniques but complement them, creating hybrid manufacturing approaches that leverage the strengths of multiple methodologies.

Material science continues advancing alongside manufacturing technologies. Researchers are developing gasket materials with “smart” properties—able to respond dynamically to changing conditions or provide real-time performance data. These developments represent the next frontier in precision engineering, where the distinction between the gasket and the monitoring system begins to blur.

The companies that will lead tomorrow’s gasket industry are those investing in both technological capabilities and human expertise today. They recognize that while advanced equipment enables precision, it’s the knowledge and skill of their engineering teams that transforms these capabilities into innovative solutions. This balance between technology and expertise defines the essence of precision engineering in modern manufacturing.

The art of precision engineering in manufacturing processes continues to evolve, driven by customer demands for ever-higher performance and reliability. For industries depending on critical sealing solutions, this evolution promises components that not only meet today’s requirements but anticipate tomorrow’s challenges. The manufacturing future belongs to those who master both the science and the craftsmanship of precision.